Today I have begun "closing up" my motor. I have timed, closed cams and installed, adjusted valves. This was the 2nd of the tasks I was rather dreading and proved to be worthy of the angst. I have found that while Wayne's book is remarkably comprehensive and an invaluable resource it still expects that one has at least a general understanding of how these things work and the ability to improvise or figure out a few things.

First the panic:

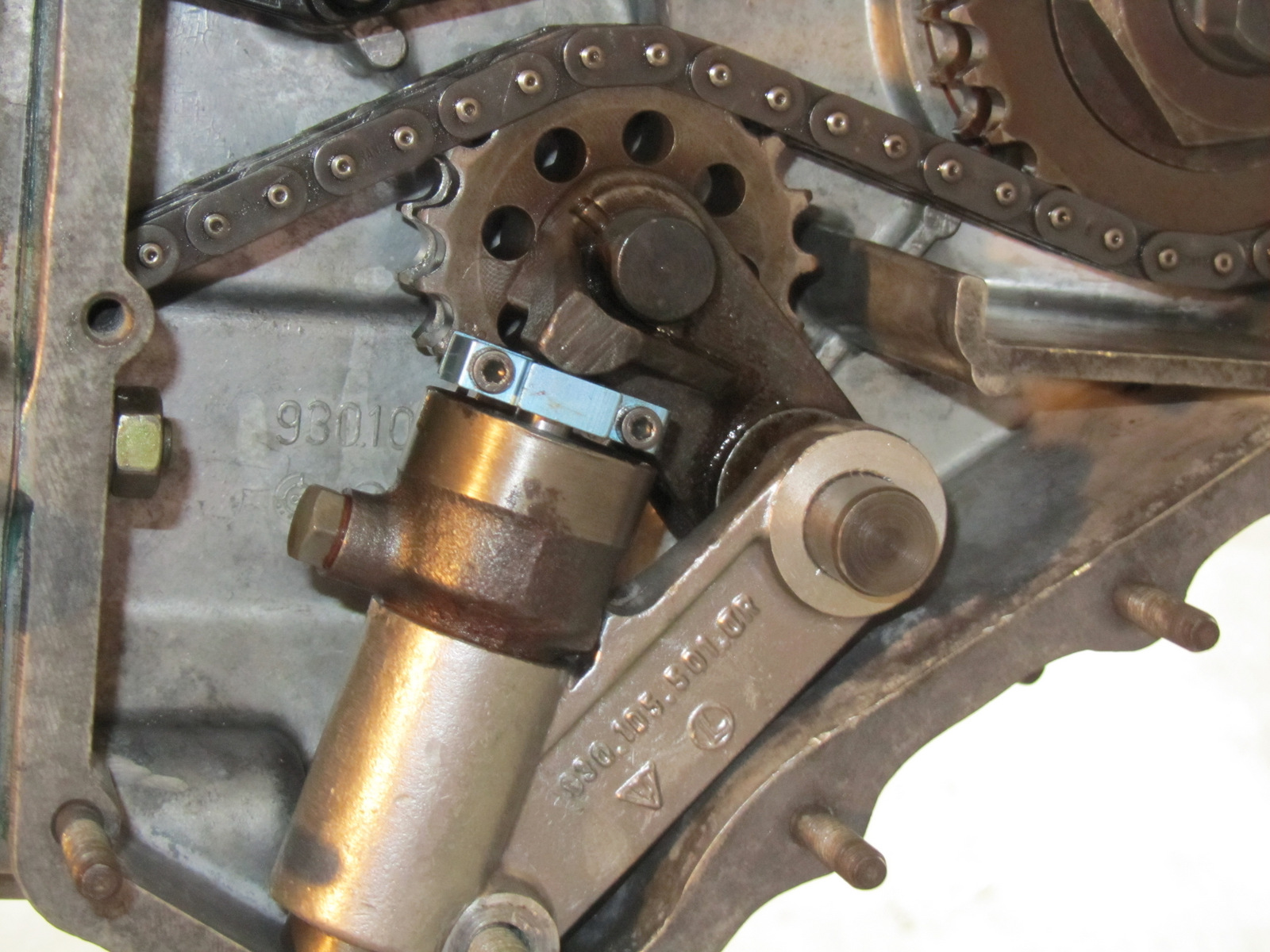

Note my rather ingenious application of "idler pulley tensioners". You are supposed to keep a good deal of pressure on the chains via the idlers for setting the cam timing. I don't have the mechanical tensioner for the right side and quickly discovered these clamps I use for woodwork w/ nice soft faces and very strong ratcheting give an excellent hold on the pulleys.

Either I missed it (even after re-reading a couple of times) or it really is glossed over but I had my cam nuts tightened down (but no pin installed yet) from the previous step. When I started the timing procedure by getting the crank to TDC I found at about 800° my engine locked and wouldn't turn. Turn back an equal amount and the same. Here is where panic set in (seeing some forgotten step and a teardown coming). But I fought it back and began to deduce why, quickly I found that the #4 intake rocker I'd just installed was making the valve hit the piston.

So I deduced one is supposed to have those nuts loose so the cams can spin irrespective of the crank position. Duh! in retrospect but like I said this seems a bit of info taken for granted.

The rest of the timing went smoothly, following step by step, managing to keep the needle right in the middle of the setting range, but it was hardly a barrel of monkeys. I'm sure this gets easier after the first go round as do many things but it's tedious and nerve racking that first.

Then came getting the [newly rebuilt] tensioners in place. I don't have the P214 tool, but an internet search suggested several methods to get the job done without it. I ended up with the big ass screwdriver method.

That worked on the left side, but the right wasn't having it. So I improvised. For the record, faced with having to do this again I think I'll order the little piece of bent metal intended for this job or make one myself. I got it done but I feared for putting too much stress on something getting there.

I then installed the safety collars that probably saved my engine while my tensioners were out of oil.

I got the back of the engine all buttoned up and went on to install the rest of the rockers and meticulously adjust all the valves. Now that chore, even though not particularly enjoyable IS much much easier with the engine on a stand as opposed to stuffed in the back of a fine piece of German engineering.

Feel like I'm actually getting somewhere!